THERMALLY BROKEN FOLDING DOORS

ADVANCE-59S, ADVANCE-60, ADVANCE-70

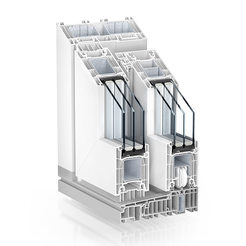

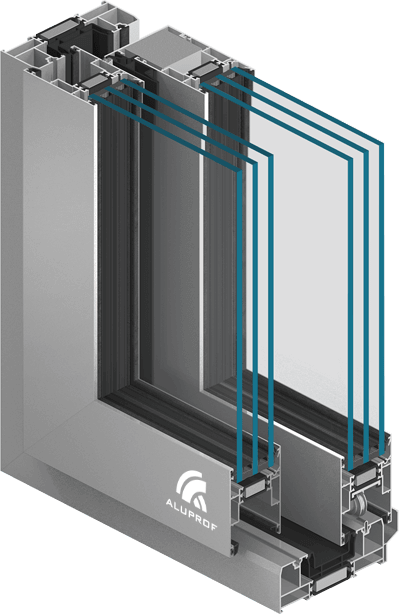

The folding door system with a thermal break presented here is a new product of Aluprof system available now , designed to meet requests and requirements of our customers, i.e. architects, investors and companies cooperating with us. The construction of folding door opening inward may be executed in ADVANCE-59S, ADVANCE-60 and ADVANCE-70 systems ( those offer a range of thremal and acoustic insulation ) . The ADVANCE-59S Casement system allows for execution of folding door opening outward.

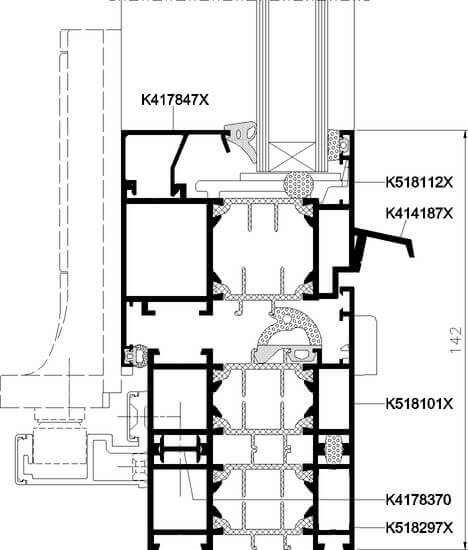

The constructional depth of profiles depends on the selected system and ranges from 50 mm (frame), 59 mm (leaf) in case of ADVANCE-59S and ADVANCE-59S Casement systems to 70 mm and 79 mm respectively in case of ADVANCE-70.

The value of heat transfer coefficient and acoustic insulation performance depends on the applied type of aluminium system. Due to special construction of profiles and application of working templates, the folding door features a very simple and time-efficient prefabrication method. Frame and leaf profiles are equipped with moulded grooves of the dimensions suitable to accommodate multi-point security locking system and connecting members compliant with the EURO standard.Reliable Roto fittings are mounted in folding doors. The guide track of these fittings may be mounted either on the upper frame profile (top hung) or at the threshold (bottom Rail ). Particular systems come with different options of thresholds and solutions of their development.

Profile connection requires minimum working due to the application of supplied aluminum connecting members and additional accessories. Corner joints of “L” type are executed by cutting off frame or leaf profile ends at 45 degree, which are crimped or pinned and then aluminium cleats inserted into the inner chambers of profiles are glued with two-component adhesive CORALGLUE. Application of glue ensures rigid connection and tightness of the joint, while the cleats guarantee that the connected profiles retain perpendicularity. Crosswise connections of “T” type are performed by pinning crosspieces with inserted cleats and gluing with CORALGLUE.

Glazing, closing and central gaskets are made of synthetic rubber - EPDM. Most gaskets are fitted continuously without corner trimming, by joining two ends of the gasket in mid-length of the upper transom bar of the window frame. Such glazing technique ensures perfect tightness to water and air infiltration.

Central gaskets are trimmed at 45o angle and glued in the corners or at the right angle and glued to a rubber corner.

Each construction in external development must be equipped with an efficient system of water deflection and ventilation from the window pane chamber and the chamber between the leaf and frame. Ventilation and drainage holes are protected from the outside with plastic covers. Product available in a whole range of RAL colour!